Welcome to Liaoyang Qingzhou Machinery Imp.& Exp. Co., Ltd

Toggle Navigation

CIP

1. The high-pressure water thoroughly wash inner surface of the chamber and condenser.

2. Equipped with large flow rate CIP pump.

3. Fixed with CIP tubing that automatically drains the residual water.

4. Use rotary and fixed nozzle with 360-degree spray.

5. The hydraulic system uses isolated retractable corrugated tube.

Characteristics

1. Standard configuration, uses double stage oil sealing revolving plate pump.

2. Option: ULVAC or Edwards pump.

3. Equipped with two vacuum probes, for measuring the vacuum level of freeze drying chest and pump respectively.

4. Option: condenser type vacuum meter.

5. There are two methods for drying chest vacuum level control:

5-1. Drying chamber vacuum level controls the opening and closing of the air inlet valve, introduces the sterilized air from sterilized room.

5-2. Drying chamber vacuum level controls the opening degree of the big butterfly valve to reach the purpose of controlling the vacuum level.

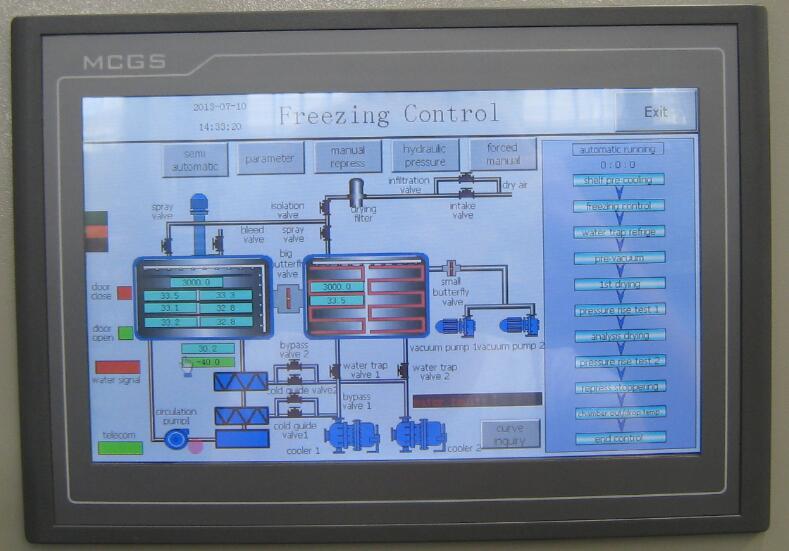

Control and optimum disposition

The control system of the freeze drier provides a reliable whole procedure control for the freeze drier. It has advanced functions of display, control, recording, printing and alarming. The control system has the following characteristics:

1. The main air switch, transformer and AC contactor fixed in electric cabinet are Siemens products. The electric cabinet is secured on machine frame. All machine pump motors are equipped with overheat protection, solenoid valve and heating circuit are equipped with separate protection.

2. The display screen uses touch screen, PLC programmable logic controller, indicating light, sound-light alarming system and etc.

3. Temperature measuring, pressure measuring, the components can work normally under high temperature, ultra-low temperature and high vacuum level with high reliability.

4. The control system can display the running status of all components of the whole system, and can store and process the operation information and various data. It can provide procedure recording report of whole freeze-drying process. It can set freeze-drying curve, monitor each status in freeze-drying procedure. It can alarm on failure or abnormal situation, provide checking for maintenance, the operator can set and modify data and steps.

Technical Parameter

| Model | LPGZL 0.5 |

| Shelf area (m2) | 0.5 |

| Shelf size (mm) | 300X450 |

| Number of shelf | 4+1 |

| Shelf spacing (mm) | 80 |

| Shelves level | ±0.5mm/m |

| Shelf surface roughness (Ra) | ≤ 0.4µm |

| Shelf temperature scope(°C) | -55~+70 |

| Shape of machine | column |

| inner surface polish (chamber) | mirror |

| Structure and shape of water capturer | horizontal cylinder |

| Lowest temperature of water capturer (°C) | -75 |

| Capturing amount of water condenser (kg) | 10 |

| Control system | automatic+manual |

| Power of whole machine (Kw) | 5.5 |

| Cooling water amount (m3/hr) (1.5≤ P≤ 2bar, T≤ 25°C) | 3 |

| SIP (option) | No |

| CIP (option) | √ |

| Weight of whole machine (kg) | 730 |

| Overall dimension LXWXH (mm) | 1200X1100X2050 |