Welcome to Liaoyang Qingzhou Machinery Imp.& Exp. Co., Ltd

Toggle Navigation

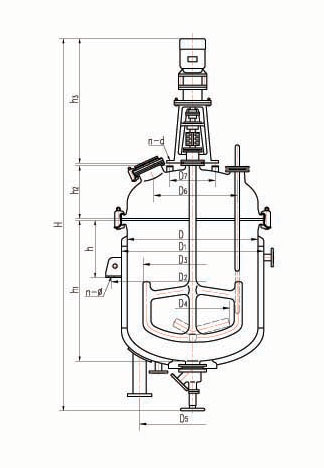

| Volume | Nominal Volume | 50L ~5000L |

| Total Volume | 71L ~610L | |

| Design Temperature | 0-180°C | |

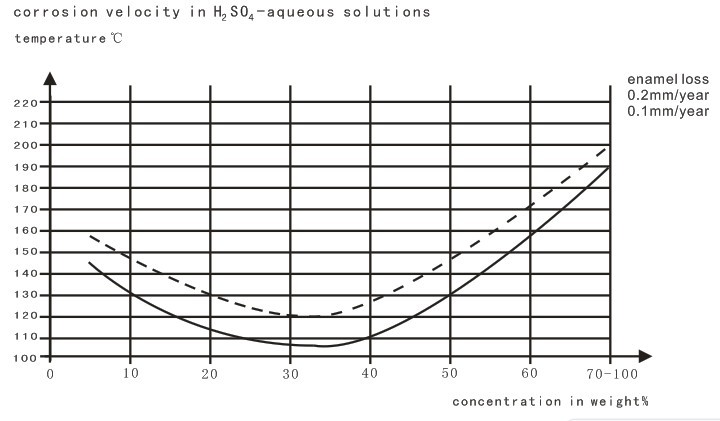

| Heat Transfer Area | 0.34~13.2 m2 | |

| Design Pressure | Cylinder | Stuffing 0.2Mpa |

| Mechanical Seal 0.4 Mpa | ||

| Jacket | 0.6 Mpa | |

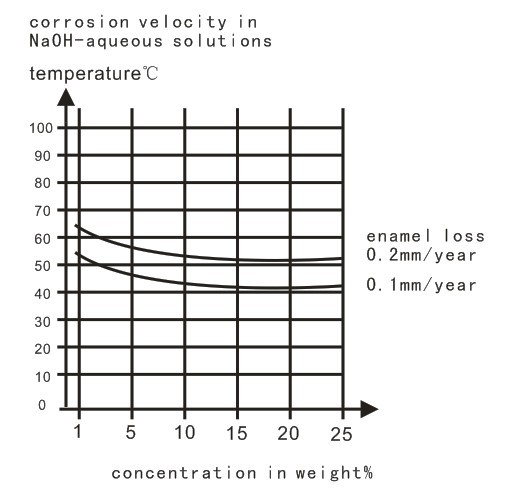

| Agitating Speed | Frame/Anchor | 60 r/min |

| Impeller/Paddle | 130 r/min | |

| Motor & Reducer | Motor Type | Y100L2-4-B5 |

| Frame Type | BLD22-23Q | |

| Impeller Type | BLD22-11Q | |

| Motor Power | 0.75~11kw | |

| Net Weight | 480~4760 kgs | |

| Model (L) | Dimension | Heating System | Weight (Kg) | |||||||||||||||

| D | D1 | D2 | D3 | D4 | D5 | D6 | D7 | N-φ | n-d | h1 | h2 | h3 | h4 | h |

Ventilator pipe |

Ventvalve | ||

| BFK50 | 500 | 602 | 718 | 420 | 300 | 500 | 380 | 240 | 4-18 | 4-M16 | 400 | 280 | 850 | 300 | 1940 | 2-25 | G1/2” | 480 |

| BFK100 | 600 | 702 | 818 | 500 | 360 | 600 | 420 | 240 | 4-18 | 4-M20 | 550 | 315 | 850 | 320 | 2030 | 3-25 | G1/2” | 550 |

| BFK200 | 700 | 804 | 930 | 620 | 420 | 670 | 540 | 320 | 4-23 | 4-M20 | 700 | 334 | 913 | 420 | 2380 | 4-40 | G1/2” | 728 |

| BFK300 | 800 | 904 | 1032 | 703 | 480 | 760 | 600 | 320 | 4-23 | 4-M20 | 810 | 365 | 913 | 370 | 2503 | 4-40 | G1/2” | 1020 |

| BFK500 | 900 | 1004 | 1136 | 803 | 540 | 800 | 630 | 320 | 4-23 | 4-M20 | 980 | 395 | 945 | 400 | 2650 | 4-40 | G1/2” | 1247 |

| BFK1000 | 1200 | 1304 | 1480 | 1100 | 720 | 1100 | 840 | 320 | 4-30 | 4-M20 | 1200 | 470 | 1120 | 500 | 3205 | 4-50 | G1/2” | 1760 |

| BFK1500 | 1200 | 1304 | 1480 | 1100 | 720 | 1100 | 840 | 410 | 4-30 | 4-M20 | 1550 | 470 | 1120 | 500 | 3555 | 4-50 | G1/2” | 1940 |

| BFK2000 | 1400 | 1524 | 1700 | 1300 | 840 | 1300 | 1000 | 410 | 4-30 | 4-M20 | 1500 | 520 | 1149 | 490 | 3570 | 4-50 | G1/2” | 2334 |

| BFK3000 | 1600 | 1754 | 1934 | 1440 | 800 | 1228 | 1120 | 450 | 4-30 | 4-M20 | 1740 | 560 | 1300 | 600 | 4100 | 3-50 2-70 | G1/2” | 3205 |

| BFK5000 | 1750 | 1904 | 2440 | 1575 | 900 | 1200 | 500 | 4-30 | 4-M24 | 2280 | 610 | 1460 | 700 | 5100 | 3-70 2-80 | G1/2” | 4616 | |

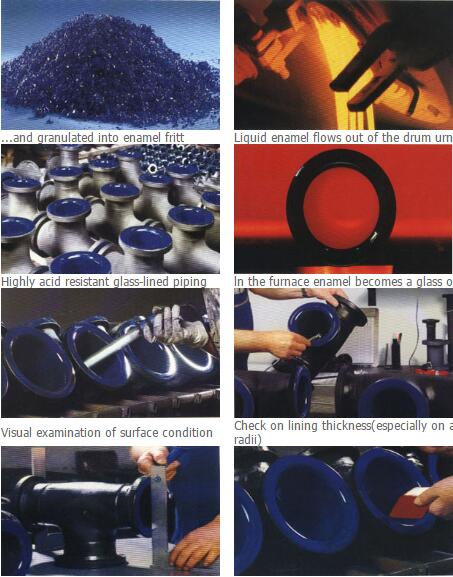

| Test Item | Results | Standard |

| Mechanical Impact resistance of glass-lined layer | >220 x 10-3 J | GB25025-2010 |

| Enamel Thickness (mm) | 0.8~2.0mm | GB25025-2010 |

| Preliminary Spark Test (V) | 20kV | GB25025-2010 |

| Final Spark Test(V) | 7kV | GB25025-2010 |

|

Thermal/Cooling shock resistance of glass-lined layer (℃) Cooling Impact: Thermal Impact: |

110℃ 120℃ |

GB25025-2010 |

| Design Temperature (℃) | 0℃~180℃ | GB25025-2010 |

|

No. |

Medium Name |

Concentration |

Temp. |

Corrosive Rate mm/y |

No. |

Medium |

Concentration |

Temp. |

Corrosive Rate mm/y |

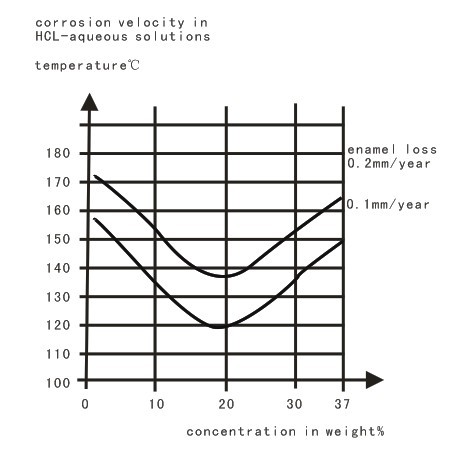

| 1 | HCL | <35 | <105 | <0.005 | 22 | Al2 (SO4)3 | 20-50 | <105 | <0.005 |

| 2 | HCL | >5 | >105 | 0.02-0.05 | 23 | NH4 Cl | <50 | <105 | <0.005 |

| 3 | HNO3 | 5-75 | <105 | <0.005 | 24 | HCHO | -100 | <105 | <0.005 |

| 4 | HNO3 | 100 | <60 | <0.005 | 25 | K2 SO4 | 10 | <105 | <0.005 |

| 5 | H2SO4 | <80 | 150 | <0.005 | 26 | NaCl | 50 | 105 | <0.005 |

| 6 | H3PO4 | 40 | 100 | 0.02-0.05 | 27 | C2 H2O4 | 10 | <38 | <0.005 |

| 7 | H3PO4 | 40 | >150 | >0.05 | 28 | NaF | <5 | <100 | <0.005 |

| 8 | H3PO4 | 30-80 | <100 | <0.005 | 29 | NaHSo | 20-50 | 100 | <0.02 |

| 9 | NaOH | <25 | Room Temp. | <0.005 | 30 | C2 H4 (NH2)OH | -100 | <105 | <0.005 |

| 10 | NaOH | 20 | 60 | >0.02 | 31 | C2 H4 (NH2)OH | -100 | <200 | <0.005 |

| 11 | NaOH | 20 | 80 | >0.05 | 32 | Br | 100 | <80 | 0.005-0.02 |

| 12 | NaOH | 30 | <38 | <0.005 | 33 | CCl 4 | 50-100 | <105 | <0.005 |

| 13 | Na2CO3 | 30 | 60 | <0.03 | 34 | H2 CrO4 | 20-30 | <105 | <0.005 |

| 14 | NaHCO3 | >25 | Room Temp. | <0.005 | 35 | FeCl3 | 10-40 | <105 | 0.02-0.05 |

| 15 | NaHCO3 | >25 | 100 | <0.02 | 36 | (HO3)C6H2COOH | 100 | <100 | <0.005 |

| 16 | CuSO4 | 10-50 | <105 | <0.005 | 37 | COOH(CH2) 2CH)(NH2) | 100 | <100 | <0.005 |

| 17 | CuCl2 | 10-50 | <105 | <0.005 | 38 | C6H6 | 100 | <100 | <0.005 |

| 18 | Cu (NO3)2 | 10-50 | <105 | <0.005 | 39 | C6H5OH | 100 | <100 | <0.005 |

| 19 | CH 3COOH | ~100 | <100 | <0.005 | 40 | NaNO3 | 10-50 | <100 | <0.005 |

| 20 | AlCl3 | 10 | >200 | >0.05 | 41 | Na2SO4 | 20 | <100 | <0.005 |

| 21 | AlCl3 | 30 | <105 | <0.005 | Attention: hydrofluoric acid, high-concentration phosphoric acid and high-concentration sodium hydroxide | ||||

| 22 | KAl (SO4)2 | 10-50 | <105 | <0.005 | |||||